Joe Troake

The Brick of Theseus

Seaweed is a natural product with incredible properties that is starting to be utilised increasingly in today’s climate; with local offshore farms beginning to sprout up in Cornwall, the Par Horticultural Seaweed Centre is both a processing plant for horticultural seaweed products and a community space for locals and tourists alike. While distributing these amazing products across the country it was also important to ensure that the project also gave back to the community, with spaces for events, a beautiful garden to enjoy and tourist attractions to experience; bringing people together in Cornwall and providing a new route for income in one of the most impoverished counties in England. Each “wing” of the dock represents the two areas of both ‘production’ and ‘community,’ combining in their use and processing of seaweed.

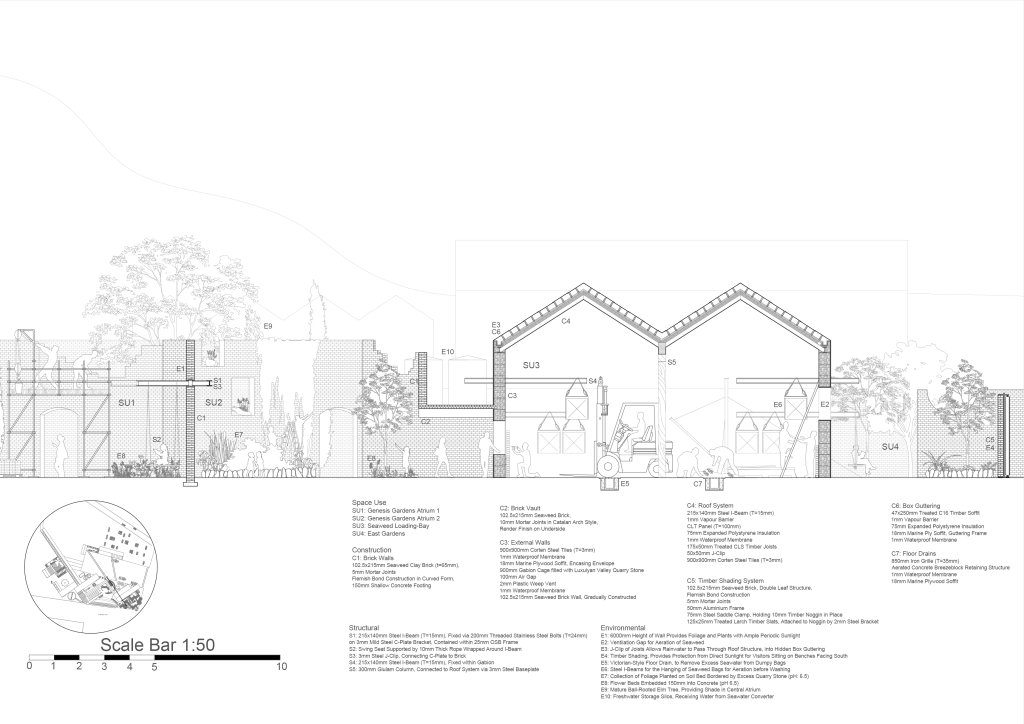

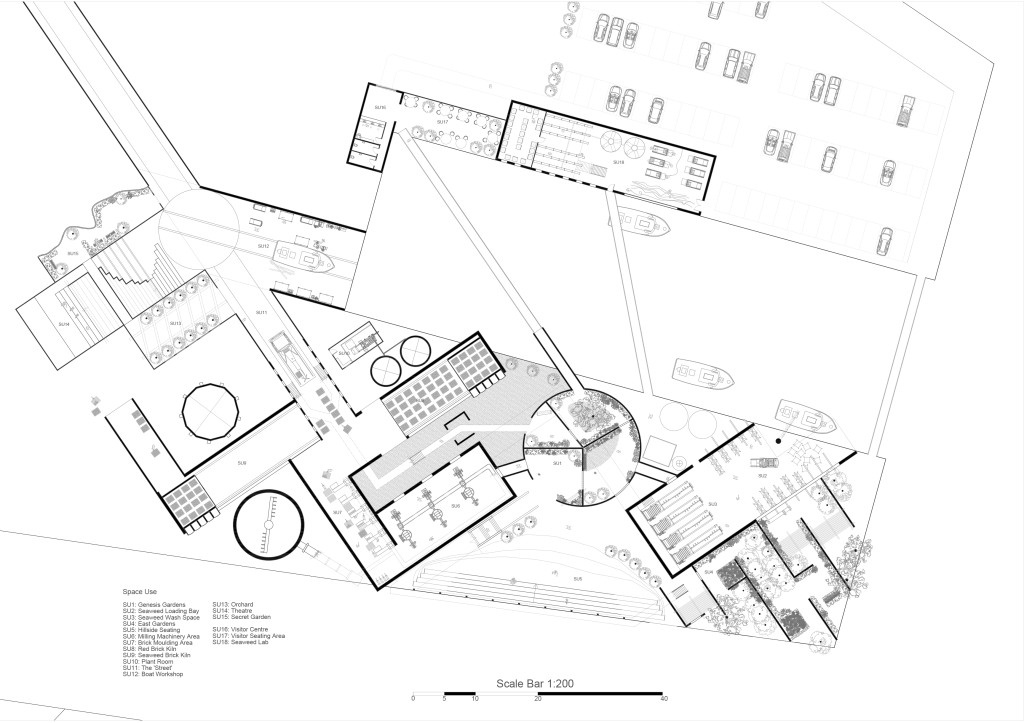

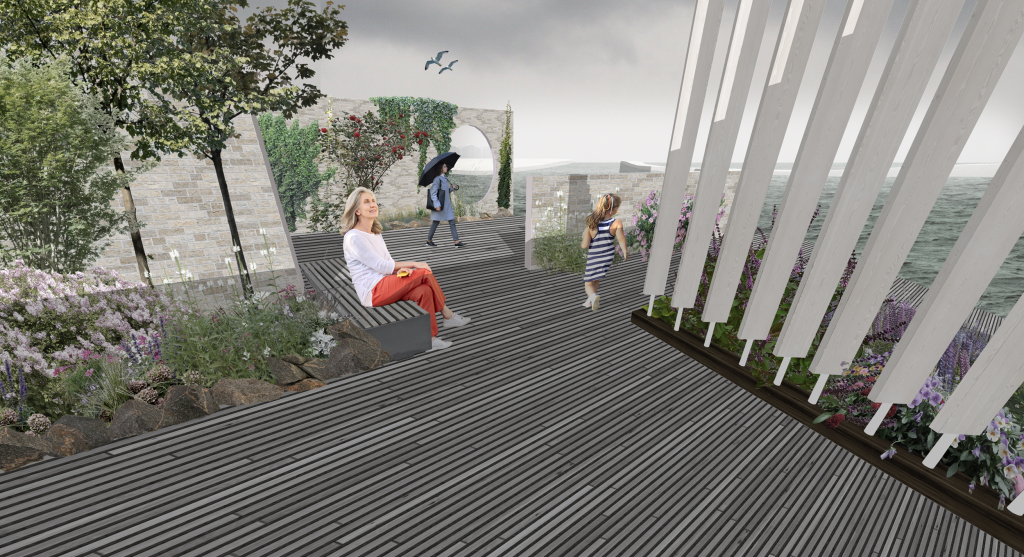

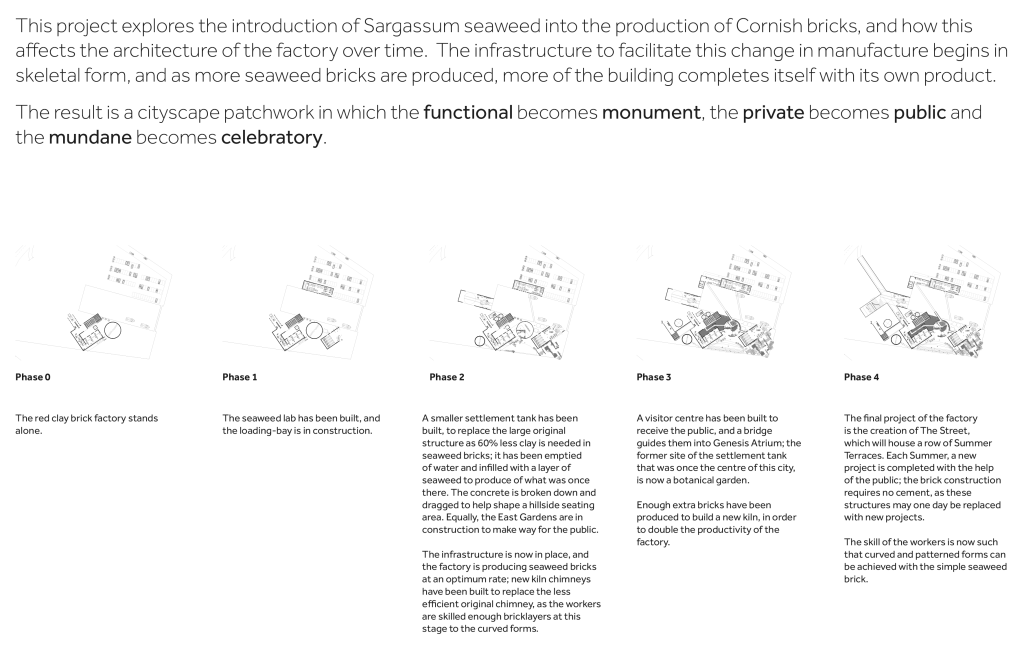

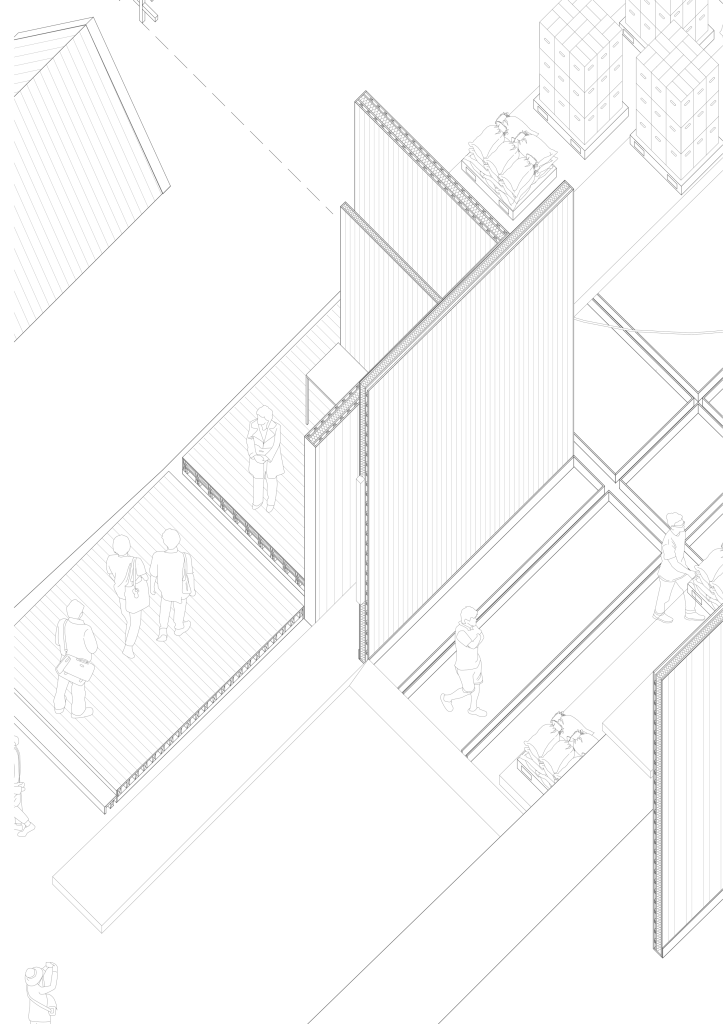

This project has been my most ambitious to date, and revolves around the novel uses of seaweed; consequently this project has been research-based and I have found seaweed bricks to be an interesting premise for a project brief. My design utilises my dissertation research into the writings of Jan Gehl on the nature of cities to produce a factory that builds itself over time with its own product and eventually has enough seaweed bricks spare to produce community-led projects each Summer. The project will become a timeline of iconography: genesis, production, redundancy, growth, monument, and finally creation – much in the same the way that a city is such.

A key space within the factory is the ‘Street’, in which traditional ideas of public space have been inverted to produce an internal passage that is adjoined by a row of open-air brick projects, completed each year by the local community in Cornwall. A lollipop man stands at attention whilst a seaweed trawler, recently towed onto land for repairs, is rotated on a turning circle, shared by outgoing delivery trucks. Time is marked by the aggregation of brickwork to the walls of this space.

Email: joetroake@gmail.com

Website Portfolio: https://jtroake.myportfolio.com/

Penzance Distribution Centre

Introduced in the heart of Reading Town, Hogmanay, the Scottish celebration of New Years, brings a large infusion of culture and festivity to the local area. Cock-a-Leekie soup, being an integral cuisine of the Scottish, accompanies the festivities. The influx of Hogmanay culture, introduced by the arrival of the Soup Facility, will indulge Reading in a host of traditions that seek to bring people together to celebrate the New Year and the fresh start that follows midnight. On New Year’s Eve in Reading, the public are invited to join in the activities, including; farming the ingredients for the soup, trying the soup, setting Juniper branches alight at midnight, Ceilidh dancing, drinking homemade Gin, and the chance to watch as the chefs produce the soup from raw ingredients on site.

Cock a Leekie , Scotland, Timber, Homemade, Feathers, New years

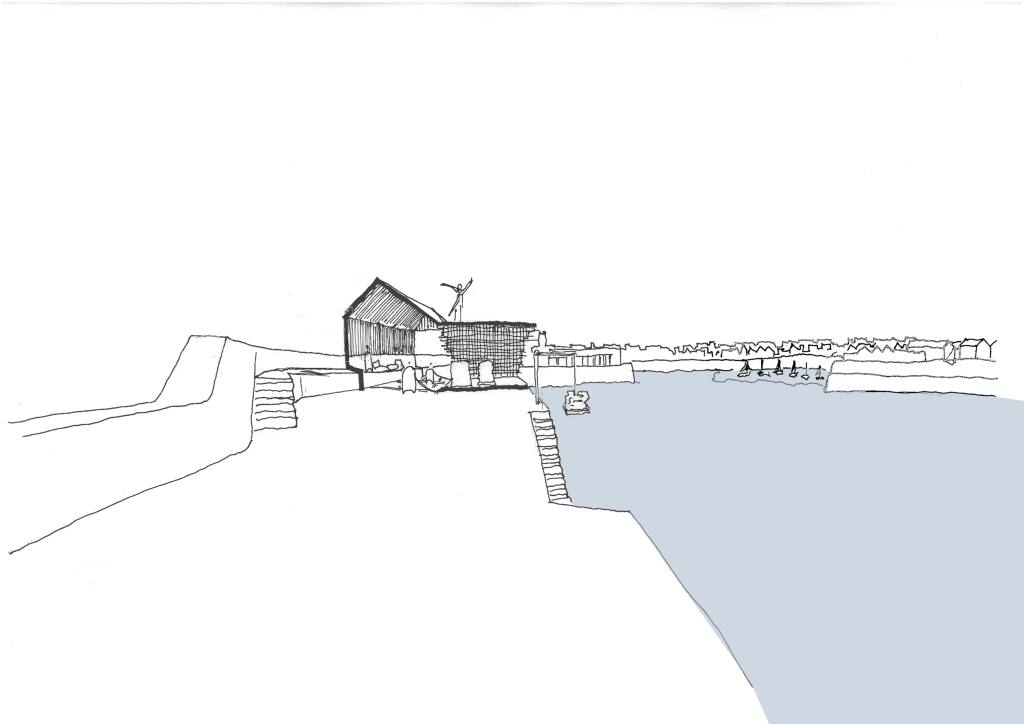

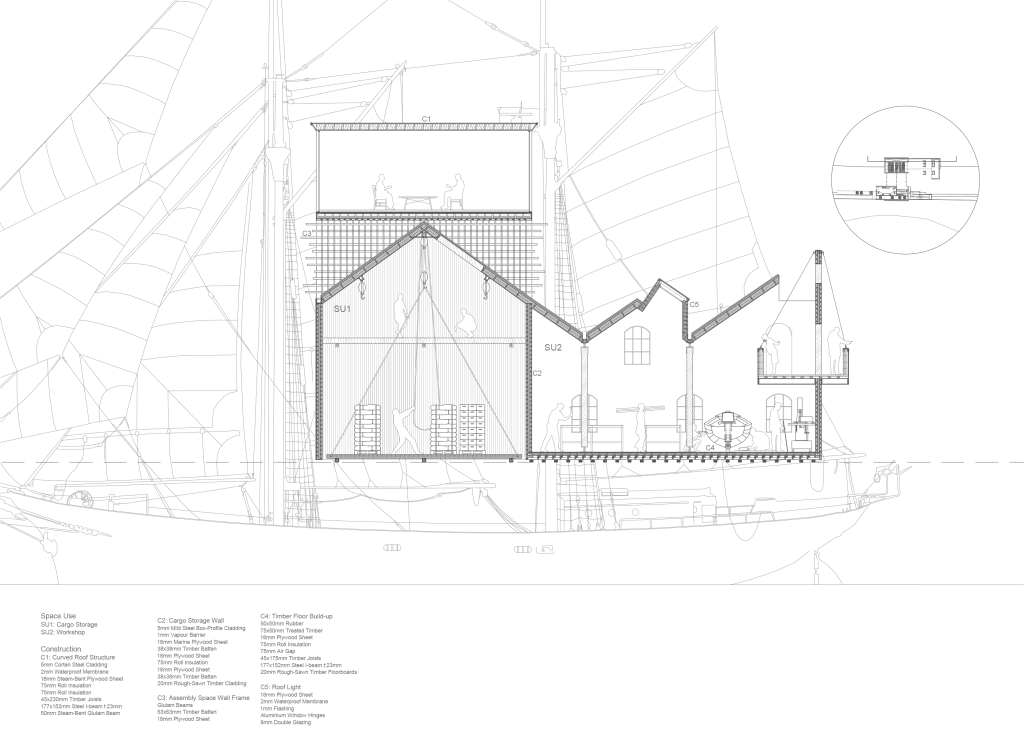

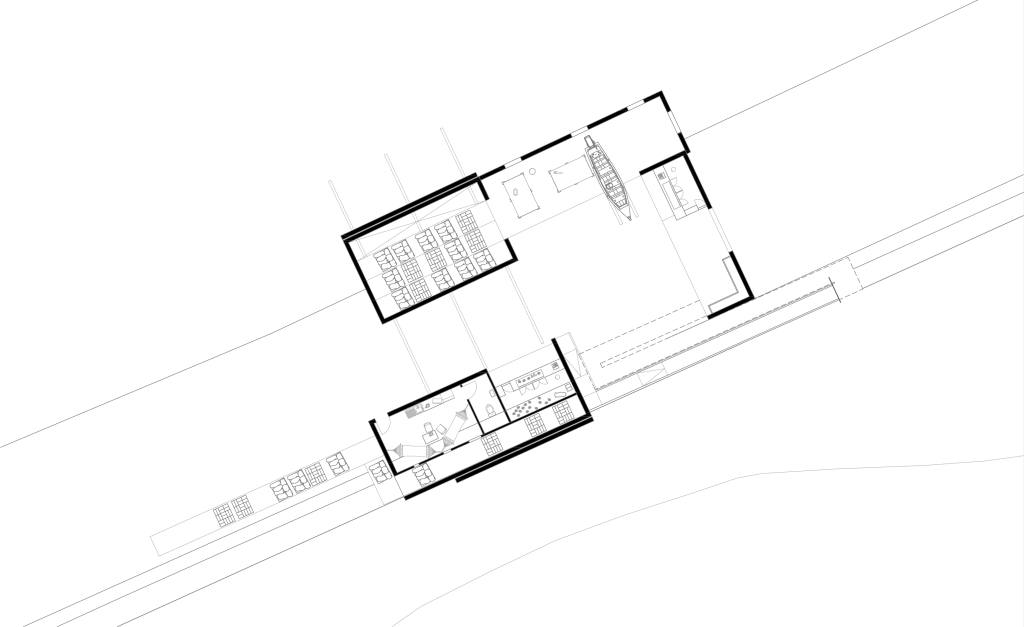

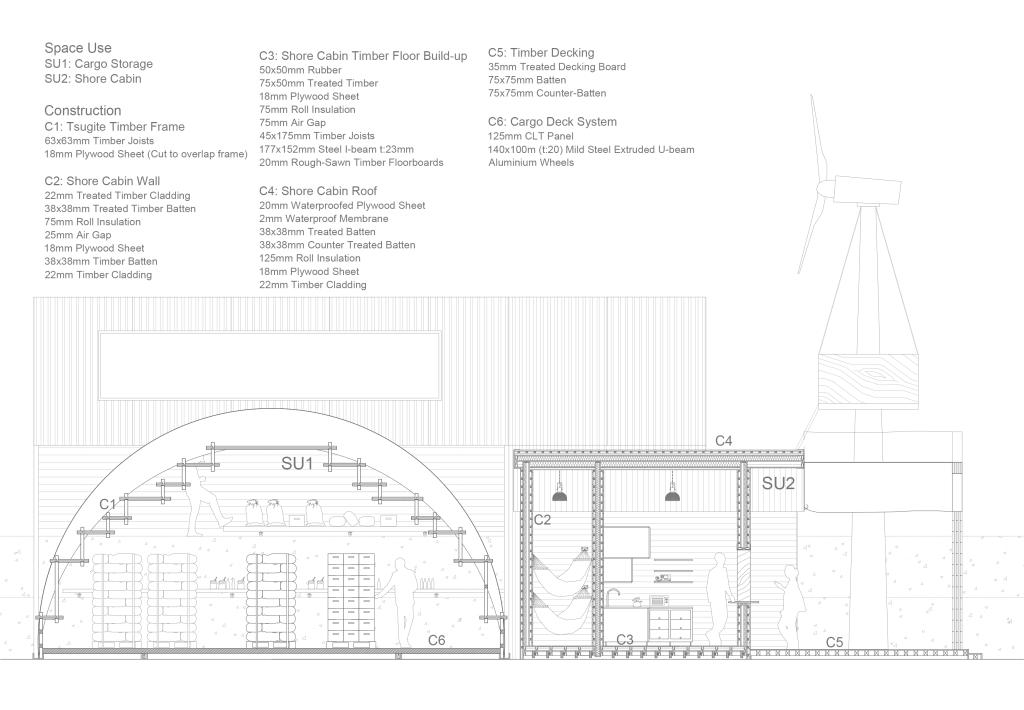

This project was split into 2 phases, the first of which consisted of a temporary timber pop-up centre on Penzance Harbour for distributing the goods of the Dutch cargo vessel, Avontuur. The primary concept in my design was that there would be an array of moving parts to transfer the goods from ship to shop-front, and to unfold the building as the process transpired. Phase 2 of the project incorporated the same spatial requirements as Phase 1, but this design was intended to be more permanent in its deployment and include a marketplace, nautical workshop, and sick bay, as well as an assembly space for talks and workshops on the ocean/environment.

The kinetic aspects of Phase 1 were brought forward within Phase 2, present in the horizontal planes, rather than just vertical. A courtyard space is extended out along the harbour, enclosed by a fresh fish market and a boat repair workshop which spills into the public space. A staircase circulates seasick crew members into a space isolated from the water, whilst also guiding the public through the ceiling space of the workshop, before wrapping around the loading house into the upper assembly space.